The success of any engineering challenge hinges on the clarity and objectivity of its judging criteria. We've carefully designed a comprehensive set of guidelines to ensure that your hard work and ingenuity are recognized and rewarded. Our judging criteria go beyond technical proficiency; they embrace sustainability, the teams competences and motivation and your approach towards future customers —the qualities that define engineering's true spirit.

In this section, we'll take you through the core components of our judging criteria, designed to accommodate the diverse range of engineering disciplines participating in the challenge. Whether you're working in aerospace, biotechnology, civil engineering, robotics, or any other field, our criteria are adaptable and versatile.

What to Expect

Your innovation has the power to shape the future and improve lives across the globe. With these criteria as our guiding principles, we aim to recognize and celebrate those who rise above the challenges and shine as beacons of innovation in the engineering world.

Judging Criteria

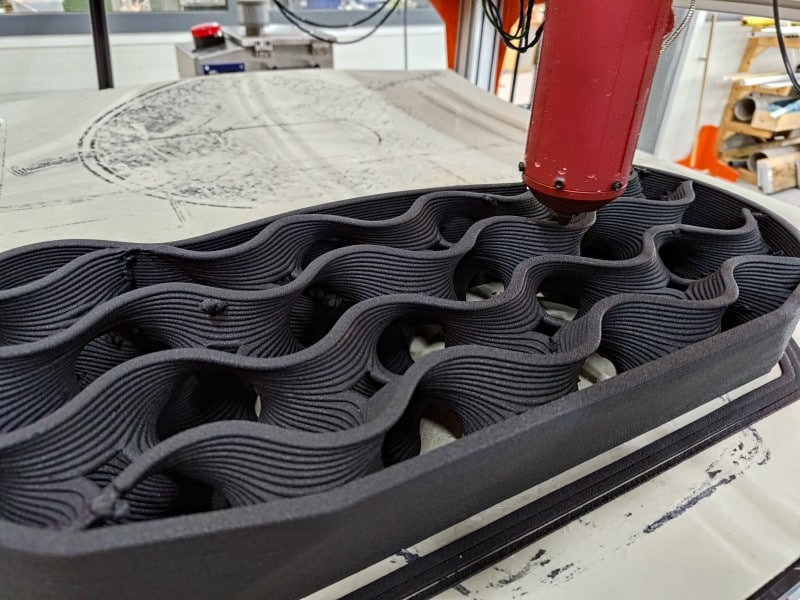

In the 3D Printing Fused Granulate Fabrication (FGF) Engineering Challenge, submissions are equally evaluated based on three criteria:

- Feasibility (technical and commercial)

- Scalability (manufacturing and team)

- Sustainability

In the judging process, all criteria have the same weightage and are hence equally important.

Startups and scaleups typically test their first (functional) prototypes, so called beta-versions, with a selective set of customers to get valuable feedback in an early stage of your development. This approach reduces time-to-market and avoids wasting resources (time and money). A great way to check both technical and commercial feasibility (in an early stage of development) is to create an MVP. This is a Minimum Viable Product, let’s say 60-80% ready that you’re going to test with a small audience to get early feedback. This first step is followed by multiple iteration loops. Typically, the final product (based on customer feedback) is not what you envisioned at the start of your journey. We recommend reading ‘The Lean Startup’ by Eric Ries (https://leanstartup.co/team/eric-ries/) to get more insights in this approach.

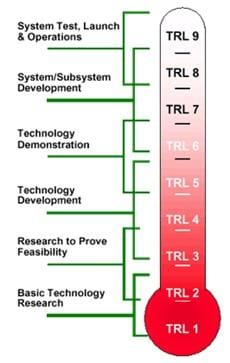

Technical feasibility is evaluated by a team of technical experts who assess the technical readiness, often referred to as TRL (Technical Readiness Level).

Teams that can demonstrate customer testing or have entered in commercial sales (of beta-versions or beyond) are favored, as it indicates a higher readiness level.

Although the TRL scale was initially developed by NASA, it has been adopted by numerous other organizations, including the European Union, for easy application across various industry sectors. The US Department of Defense (DOD), the Department of Energy (DOE), the Air Force, the oil and gas industry and the European Space Agency (ESA), all use the TRL scale. NASA introduced the TRL to enable more effective assessment and communication of technology maturity and it can also serve you to assess your product as well, even if your product is not intended for aerospace. Our judges assess the submission’s technical readiness based on the TRL scale.

TRL 1: Observation and description of the functional principle

TRL 2: Description of the application of a technology

TRL 3: Demonstrating the functionality of a technology. Experimental proof-of-concept.

TRL 4: Experimental setup in the laboratory. Technology validated in lab / testing environment.

TRL 5: Test setup in operational environment. Technology validated in industrially relevant environment.

TRL 6: Prototype in operational environment. Technology demonstrated in relevant environment.

TRL 7: Prototype in use (in operational environment).

TRL 8: Qualified system with proof of functionality in the area of application.

TRL 9: Qualified system with proof of successful use. Actual system proven in operational environment (competitive manufacturing).

Source: https://en.wikipedia.org/wiki/Technology_readiness_level

Commercial feasibility is largely depending on your business model.

While uniqueness, differentiation potential, and the value proposition play significant roles, we adopt a holistic approach, considering the entire business model. We welcome transactional, service-based, and circular business models (or elements thereof) in our Engineering Challenges.

To gauge your level of differentiation potential and gain insights into brand positioning, we recommend reading ‘Find your Zag’ by Marty Neumeier (https://www.martyneumeier.com/), a digestible resource with practical guidance. To ensure that you've covered all aspects of your business model, consult the Business Model Canvas by Alex Osterwalder (https://www.alexosterwalder.com/).

Other factors considered include the innovativeness of your solutions (whether incremental, redesign, or entirely new), the industry type (existing or emerging), and the global reach of your concept

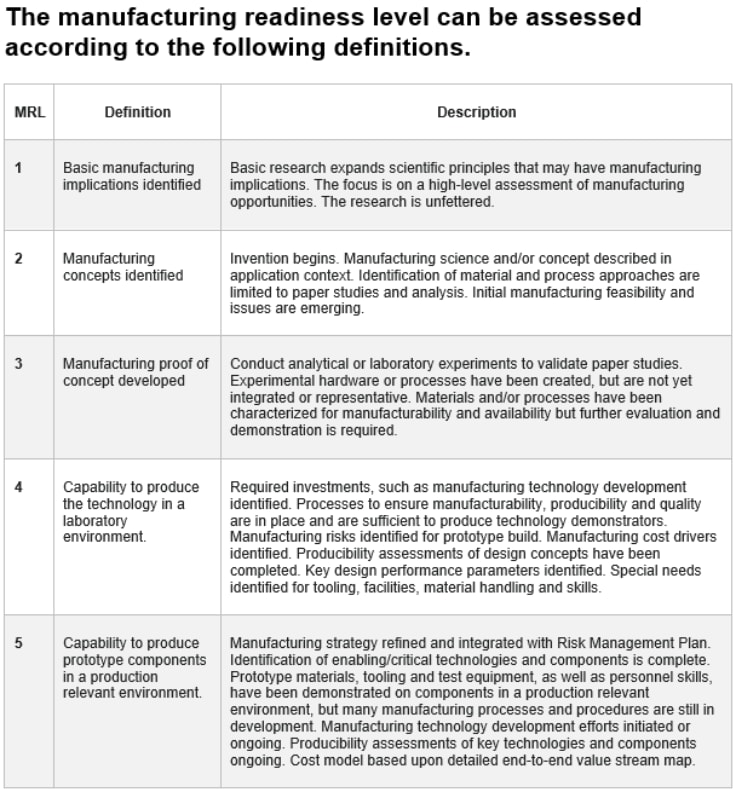

Manufacturing scalability refers to the ability of a production process to adapt, expand, or adjust in order to handle increasing demands or changes in production volume without significant loss of efficiency or increase in costs. In other words, a manufacturing process is considered scalable if it can smoothly accommodate larger production volumes without requiring substantial changes or disruptions to its operations.

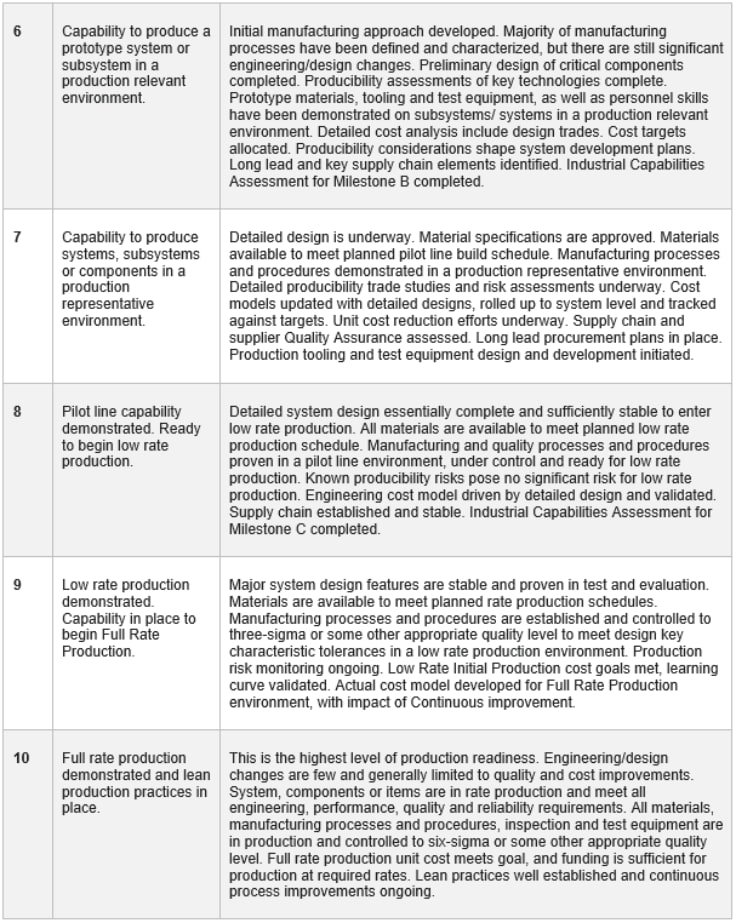

Manufacturing scalability is evaluated according to the MRL (Manufacturing Readiness Level) principles defined as follows:

Source: https://en.wikipedia.org/wiki/Manufacturing_readiness_level

Team - In addition to the manufacturing technology, we are highly interested in the team behind your submission. Do you have the right team, the appropriate competence, and partners onboard to execute within a specific timeframe? This aspect typically becomes more crucial as your company matures, transitioning from a single entrepreneur to a startup, to a scale-up, and beyond.

Not having all the necessary competences in place yet is not a disqualifying criterion, as you will gain access to our ecosystem and partners that will provide support, including funding. The key factor is having the passion and drive to see the endeavor through to completion.

Intellectual property (IP) - Owning the intellectual property of your solution is an advantage or as a minimum having done the check that you are not infringing anybody’s patent. Your work nor its use should infringe the intellectual property rights of any person. Neither Mitsubishi Chemical Group nor its partners will claim any Intellectual property rights over the content that you submit and your submission does not constitute invention assignment.

Sustainability is an important criterion in the assessment of your submission.

This encompasses various aspects, such as solutions benefiting societal well-being (e.g., assistive technologies like wheelchairs and prosthetics), waste reduction by using lesser material for production, printing with bio-based and recycled material grade, financial sustainability by reducing-costs by switching to 3DP FGF, reduced waste by having more flexibility in prototyping phase, and promoting a circular economy. Can you quantify the impact of your technology, service, or product?

For instance: Switching the manufacturing method of a car monocoque (chassis) to 3DP FGF with x% recycled grade printing pellets helped us achieve x% reduction in manufacturing cycle time and x% savings in CO2 emissions in its lifecycle.

Check out the example of how CEAD and MCG collaborated on a project with TU Eindhoven for producing an electric vehicle using 3D printed FGF: CEAD

We firmly believe in a giving-back philosophy rather than a taking approach. Solutions incorporating these aspects are typically ranked as more future proof, with a higher likelihood of long-term success in the market. Quantifying the reduction in carbon footprint and CO2 emissions savings compared to the incumbent market solution can be a compelling selling point. Our experts specializing in Life Cycle Assessments (LCA) are integral members of our jury expert panel and are integral to our ecosystem.

Interested to discover how we’re putting our sustainability strategy into practice and driving the circular economy? Subscribe to this whitepaper and read what does the circular economy mean to us, and why is it at the centre of our business strategy.

.png/jcr:content.png)

HESITANT TO PARTICIPATE?

Are you unsure about your project? Do you think your project is too small? You don't know if your project fits into this Challenge? You have some unanswered questions? Well don't hesitate and let's get in touch. We're here to help, guide and support you. Send your short message to growthgarage@mcgc.com and indicate what fits you best : a call or a feedback mail or ..... just name it! Guaranteed response in 24h!