Feasibility

While we applaud imaginative thinking, your idea needs to also be a realistic proposal that makes the most innovative use of our materials and technologies.

Growth Garage is a business accelerator program from the Advanced Materials Division of Mitsubishi Chemical Group (MCG). Our mission is to support and grow new ideas using our technologies and advanced engineering materials to help tackle some of today’s most significant engineering challenges.

Growth Garage - in partnership with Wevolver - is inviting engineers, designers, entrepreneurs, innovators, start-ups, companies and students to submit their ideas, technologies, products and services as part of the 2022 Circular Economy Challenge.

We are looking for innovators throughout the plastics circular economy who want to make use of advanced low carbon footprint engineering plastics or have developed innovative recycling technologies for advanced engineering plastics.

The winners of the challenge are invited to participate in a pilot program with Mitsubishi Chemical Advanced Materials to take their idea to the next level. The total value of this program is $25,000.

The challenge is looking for participants in two key areas:

1. Recycling Technology

2. Products & Parts.

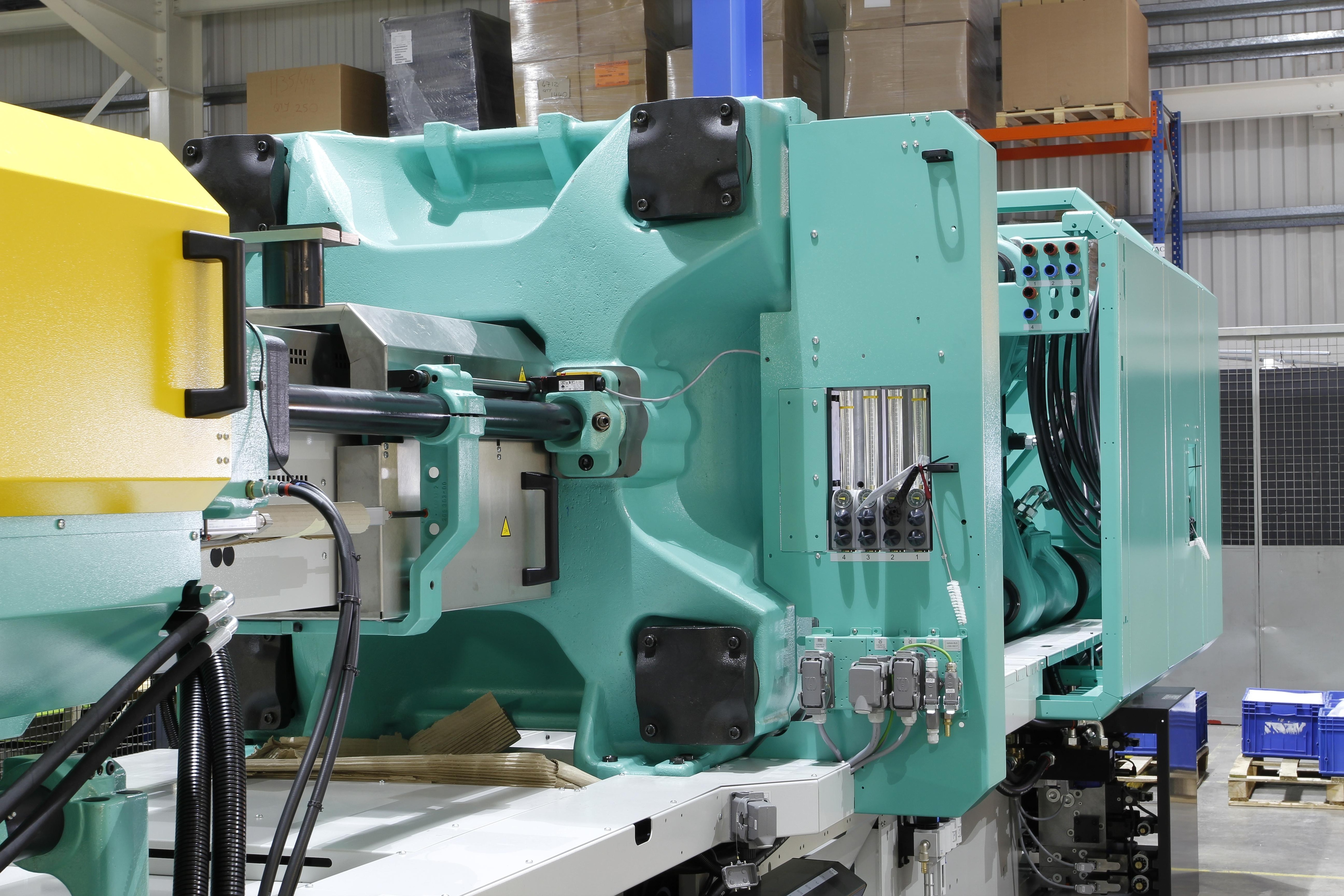

Mechanical and/or chemical recycling is key to produce sustainable thermoplastic polymers, minimize landfill, close-the-loop, and facilitate the implementation of the Circular Economy.

Are you an innovator that has developed technology that enables the recycling of engineering plastics or improves their recycling process? Does your technology improve the efficiency of mechanical recycling (collecting, identification, sorting, cleaning, grinding, regranulation, etc), or is a novel chemical or physical recycling technology?

Submission requirements:

Are you a product designer that works within or wants to join the circular economy? Have you designed, developed, or manufactured products or parts with low carbon footprint engineering plastics for the circular economy?

Submission requirements:

These are the main criteria each jury member focus on when judging each submission. All ideas are objectively analyzed and carefully considered.

Feasibility

While we applaud imaginative thinking, your idea needs to also be a realistic proposal that makes the most innovative use of our materials and technologies.

Scalability

We're looking for fresh ideas from entrepreneurial businesses that are ready to scale up but may still need some support.

Circularity

Our commitment towards circular economy means that every entry will be judged on how much of a positive impact it can make on the environment.

All submissions will be judged according to 3 categories:

All categories are of equal importance to judge the submissions.

The technical feasibility is judged by a team of technical experts that assess the technical readiness, often referred to as TRL (Technical Readiness Level).

In Category 1, Recycling Technology, We’re looking for inventive and original ideas that improve the mechanical or chemical recycling process and support the production of low carbon footprint materials

(thermoplastic polymers) that have a high recyclable content. The team will look into the following questions:

In Category 2, Products and Parts, we are looking for innovative students, product designers, start-ups, scaleups and established businesses who want to work within the Circular Economy and want to design, develop or manufacture products or parts with low carbon footprint engineering plastics. Some key questions:

Owning the intellectual property of your solution is an advantage or as a minimum having done the check that you are not infringing anybody’s patent. Your work nor its use should infringe the intellectual property rights of any person. MCG Advanced Materials nor its partners will claim any Intellectual property rights over the content that you submit and your submission does not constitute invention assignment.

The commercial feasibility very much depends on your business model.

Often the commercial feasibility is directly linked to the uniqueness or differentiation potential or the Value Proposition and although very important, we take a more holistic approach and look into the entire business model. Transactional ,service and circular business models are all welcomed in this Engineering Challenge.

To check the level of differentiation potential and get reflection on your brand positioning, we advise to read the book ‘Find your Zag’ by Marty Neumeier (https://www.martyneumeier.com/), which is easy digestible and includes some practical guidance. To ensure that you covered all elements to build your business model, we advise to look at the Business Model Canvas by Alex Osterwalder (https://www.alexosterwalder.com/).

A great way to check the commercial feasibility (in an early stage of development) is to create a MVP. This is a Minimum Viable Product, let’s say 60-80% ready that you’re are going to test with a small audience to get early feedback. This first step is followed by multiple iteration loops. Typically, the final product (based on customer feedback) is not what you envisioned at the start of your journey. We recommend to read ‘The Lean Startup’ by Eric Ries (https://leanstartup.co/team/eric-ries/) to get more insights in this approach.

Teams that can show customer testing or have entered in commercial sales (of beta-versions or beyond) are favoured.

Other elements that will be considered are how radical your solutions is (incremental change, redesign or new to the world), the type of industry (existing or new) and the global reach.

We assess 2 important factors to determine readiness of scalability.

In Category 1, Recycling Technology, we will check if you are able to run your technology on lab, pilot or industrial scale and to what extend we can scale and implement your service or technology in our business.

In Category 2, products and Parts, we will assess the production methodology. What if you are successful and the numbers of products increases? Are there cost effective production methodologies that could facilitate that growth, meanwhile respecting the integrity of your product and ensuring that you can still offer your business model? Are you able to collect the parts back from your customer end-of-life (only applicable in case of a circular business model).

Besides the production technology, we are very much interested in the team behind your submission. Do you have the right team, the right competence and partners onboard to execute within a certain timeframe? This typically increases with the maturity of your company, from single entrepreneur to start-up to scale-up and beyond.

Not having all competences in place yet is not a knock-out criteria, because you will get access to our ecosystem and partners that will support you (incl. funding). Having the passion and drive to take it all-the-way is absolutely key.

Sustainability is a large playing field and is considered as one of the main judging criteria. This may include solutions that are good for the well-being of our society (for example prosthetics), reduce waste, design for recycle, reduce energy during production, improve fuel efficiency by light-weighting or friction reduction, extend the lifetime of a product or promote the circular economy.

Are you able to quantify the impact of your technology/service or product? For example:

We strongly believe in giving more back than we take. Solutions that take these elements into account are typically ranked as being more future-proof with higher chance of long term success in the market.

A quantification of the reduction of the carbon footprint and CO2 emission savings (vs the incumbent solution in the market) can be a strong selling argument.

Our experts in the field of Life Cycle Assessments (LCA) are part of our jury expert panel and are part of our ecosystem, which will become available to you when joining a Challenge as an early bird or a finalist/winner.

Challenge Winner

(Valued at $ 25,000)

As a winning Growth Garage challenger, our engineers will work in collaboration with you to:

Wevolver Community Winner

(Valued at $ 10,000)

As the Wevolver community winner, our engineers will work in collaboration with you to:

Student Award Winner

(Valued at $ 5,000)

The winning student will receive mentoring and support from MCG Advanced Materials engineers and business leaders.

The student prize package includes: